Selecting the right material is crucial for ensuring that your parts meet performance expectations and manufacturing requirements. At Alltec, we understand that the specific demands of your application—such as tensile strength, impact resistance, and thermal stability—are the key drivers in material selection. These performance needs must be balanced with processing considerations like flow rate, ejection behavior, and potential warpage to achieve optimal production results.

To enhance your project’s success, Alltec offers comprehensive support in material selection, including providing detailed resin information, conducting research, and sharing testing results to meet industry-specific standards such as FAR 25.853 for flame retardancy in aerospace applications. Our extensive experience and deep knowledge of materials allow us to recommend the most suitable options tailored to your specific needs.

To enhance your project’s success, Alltec offers comprehensive support in material selection, including providing detailed resin information, conducting research, and sharing testing results to meet industry-specific standards such as FAR 25.853 for flame retardancy in aerospace applications. Our extensive experience and deep knowledge of materials allow us to recommend the most suitable options tailored to your specific needs.

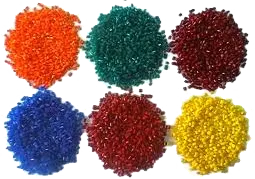

And many, many more...

Our broad range of material capabilities ensures that we can meet diverse application requirements, from high-performance engineering plastics to cost-effective commodity resins. Whether your project calls for materials with specific mechanical properties, enhanced aesthetics, or regulatory compliance, Alltec is equipped to process and deliver the perfect solution for your production needs.

By partnering with Alltec, you gain access to a wealth of material expertise and the assurance that your components will be manufactured with the highest quality materials, selected to optimize both performance and manufacturability.

Copyright 2026 Clayens Santa Maria, LLC.